-

La máquina de ensayos CBR, Marshall y uniaxiales se utiliza para realizar ensayos de compresión uniaxial y no confinada CBR

-

El dispositivo consta de un robusto y compacto bastidor de dos columnas con una viga transversal superior ajustable accionada por un pistón electromecánico

-

Se ofrecen dos modelos con capacidades de 50 kN y 100 kN

- Todos los productos

- Todos los productos

- Máquina de Ensayo CBR, Marshall y Uniaxial (Pantalla Táctil)

Máquina de Ensayo CBR, Marshall y Uniaxial (Pantalla Táctil)

https://cotecno.opendrive.cl/shop/b2-01-03-0051-maquina-de-ensayo-cbr-marshall-y-uniaxial-pantalla-tactil-592170 https://cotecno.opendrive.cl/web/image/product.template/592170/image_1920?unique=aee96d2Beneficios clave

SKU: B2-01-03-0051

Descripción General

La máquina de ensayos CBR, Marshall y uniaxiales se utiliza para realizar ensayos de compresión uniaxial y no confinada CBR.

El dispositivo consta de un robusto y compacto bastidor de dos columnas con una viga transversal superior ajustable accionada por un pistón electromecánico. Se ofrecen dos modelos con capacidades de 50 kN y 100 kN.

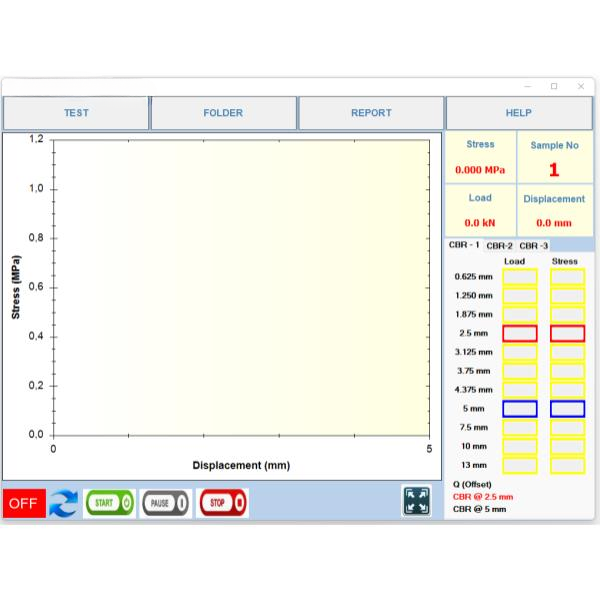

- La velocidad de ensayo se puede ajustar entre 0,001 mm/min y 51 mm/min.

- El ajuste de velocidad de la placa de carga se controla desde la unidad de lectura digital.

- Por seguridad, el recorrido vertical de la placa inferior está limitado mediante interruptores de límite.

- El sistema de medición consta de una celda de carga de 50 kN o 100 kN, según la capacidad del bastidor, instalada en la viga transversal superior para leer los valores de estabilidad, y un sensor de desplazamiento de 25 mm instalado en la columna.

Cumplimiento normativo

ASTM D2166, AASHTO T208. Platinas de compresión utilizadas para realizar ensayos de compresión uniaxial y no confinada. Se suministran completas con el conjunto de asiento de bola. Sistemas de ensayo Marshall: normas: EN 12697-34, 12697-23, 12697-12. 13108, ASTM D1559, AASHTO T245. Debe utilizarse con el molde de estabilidad de cabezal de rotura para muestras Marshall de 4” (101,6 mm) o 6” (152,4 mm) y el adaptador para cabezal de rotura para realizar ensayos Marshall. Sistemas de ensayo CBR. NORMAS: EN 13286-47, BS 1377:4, ASTM D1883, AASHTO T193, NF P94-078, UNI CNR 10009. Debe utilizarse con el pistón de penetración CBR para realizar ensayos CBR. Normas: ASTM D2166, AASHTO T208, EN 12697-34, 12697-23, 12697-12, 13108, ASTM D1559, AASHTO T245, EN 13286-47, BS 1377:4, ASTM D1883, AASHTO T193, NF P94-078, UNI CNR 10009

Especificaciones Técnicas

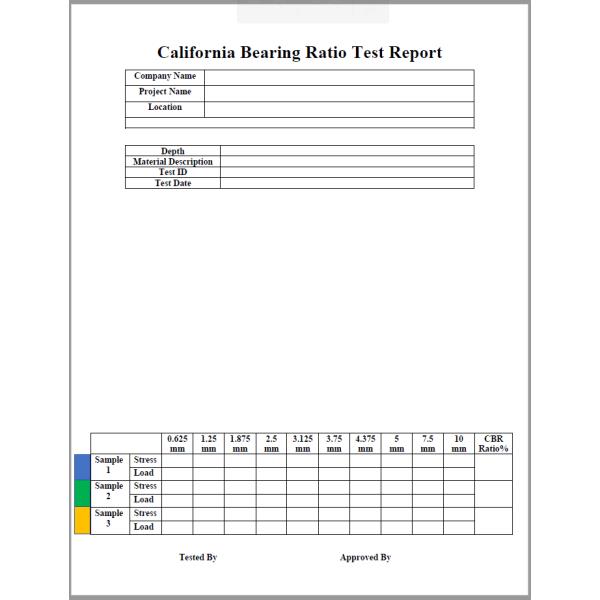

| 0.625 | 1.25 | 1.875 | 2.5 | 3.125 | 3.75 | 4.375 | 5 | 7.5 | 10 | CBR Ratio% | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||

| Sample 1 | Stress | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Load | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Sample 2 | Stress | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Load | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Sample 3 | Stress | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Load | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

Especificaciones Técnicas

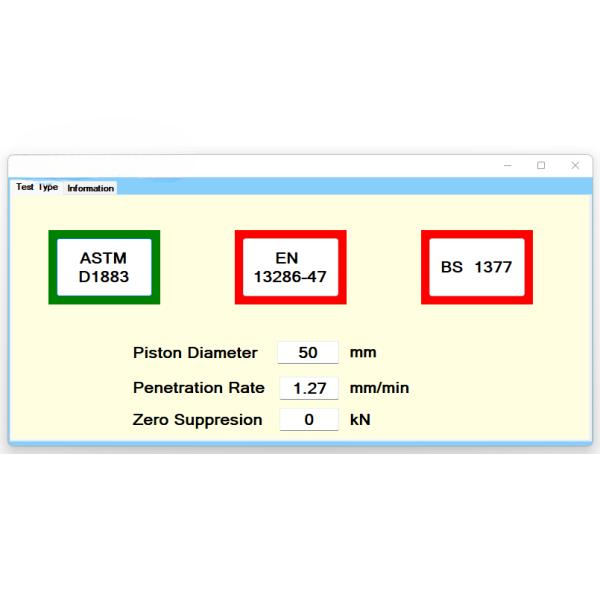

| ASTM D1883 |

EN 13286-47 |

BS 1377 |

|---|---|---|

| Piston Diameter | 50 | mm |

| Penetration Rate | 1.27 | mm/min |

| Zero Suppresion | 0 | kN |

Especificaciones Técnicas

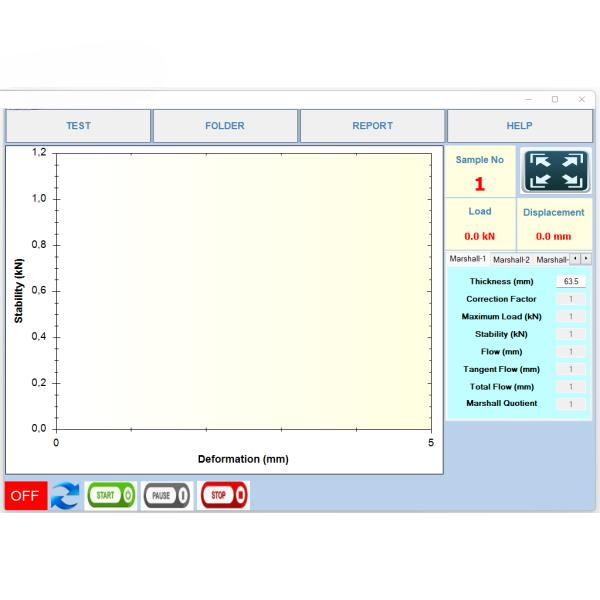

| Marshall Stability and Flow of Asphalt Mixtures | ||||||

|---|---|---|---|---|---|---|

| Company | --- | |||||

| Project | --- | |||||

| Address | --- | |||||

| Bitumen Content | --- | |||||

| Material Description | --- | |||||

| Mold Size - Test Temperature | --- | |||||

| Test Date | --- | |||||

| Average Bulk Density | --- | |||||

| Sample | Thickness (mm) | Correction Factor | Maximum L. (kN) | Stability (kN) | Flow (mm) | Marshall Q. (kN/mm) |

| Sample 1 | --- | --- | --- | --- | --- | --- |

| Sample 2 | --- | --- | --- | --- | --- | --- |

| Sample 3 | --- | --- | --- | --- | --- | --- |

| Sample 4 | --- | --- | --- | --- | --- | --- |

| Average | --- | --- | --- | --- | --- | --- |

| Tested By | Approved By | |||||

Especificaciones Técnicas

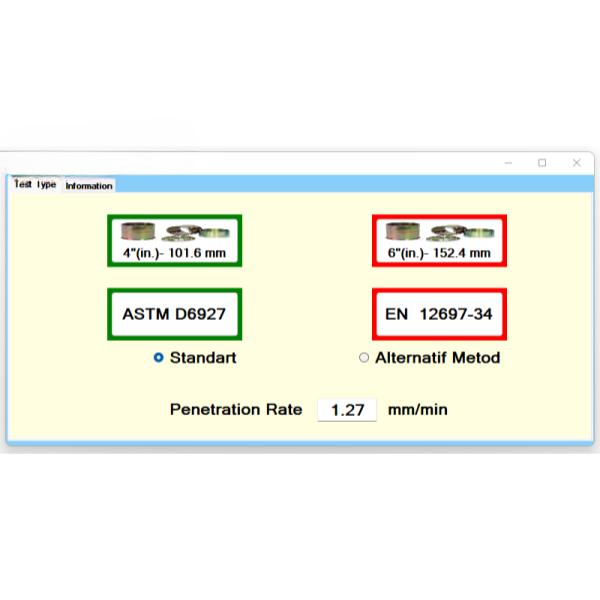

| 4"(in.)- 101.6 mm | 6"(in.)- 152.4 mm |

|---|---|

| ASTM D6927 | EN 12697-34 |

| • Standart | ○ Alternatif Metod |

| Penetration Rate 1.27 mm/min | --- |

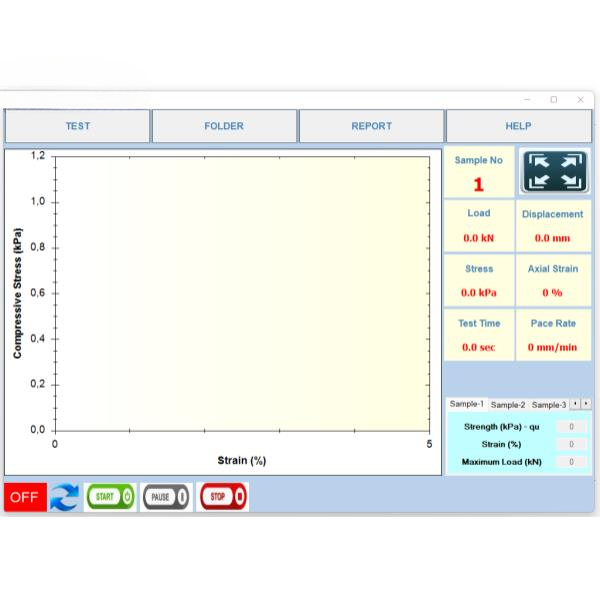

Especificaciones Técnicas

| Diameter | 50 | mm |

| Initial Length (LO) | 100 | mm |

| Initial Area (A0) | 1963.495 | mm2 |

| Weight | 520 | g |

| Heig.-Diam. Ratio | 2 | |

| Density | 2.65 | g/cm3 |

| Test Speed | 1 | mm/min |

| Axial Strain Rate | 1 | %/min |

Especificaciones Técnicas

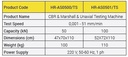

| Código | B2-01-03-0051-02 | B2-01-03-0051-04 |

|---|---|---|

| Product Name | CBR & Marshall & Unaxial Testing Machine | |

| Test Speed | 0,001 - 51 mm/min | |

| Capacity (kN) | 50 | 100 |

| Dimensions (cm) | 47x70x110 | 52X72X110 |

| Weight (kg) | 100 | 110 |

| Power Supply | 220 V, 50-60 Hz, 1 ph | |

Repuestos y Consumibles

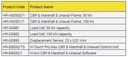

| Código | Descripción |

|---|---|

| B2-01-03-0051-01 | CBR & Marshall & Uniaxial Frame, 50 kN |

| B2-01-03-0051-03 | CBR & Marshall & Uniaxial Frame, 100 kN |

| B2-01-03-0051-09 | Load Cell, 50 kN capacity |

| B2-01-03-0051-10 | Load Cell, 100 kN capacity |

| B2-01-03-0051-11 | Displacement Sensor, 25 x 0,01 mm |

| B2-01-03-0051-08 | H-Touch Pro Max CBR & Marshall & Uniaxial Control Unit |

| B2-01-03-0051-07 | H-GUI CBR & Marshall & Uniaxial Software |

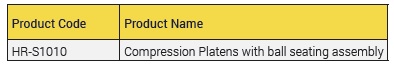

Repuestos y Consumibles

| Código | Descripción |

|---|---|

| B2-01-03-0051-12 | Compression Platens with ball seating assembly |

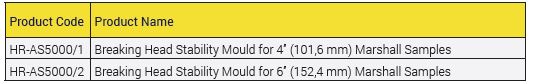

Especificaciones Técnicas

| Código | Descripción |

|---|---|

| B2-01-03-0051-05 | Breaking Head Stability Mould for 4' (101,6 mm) Marshall Samples |

| B2-01-03-0051-06 | Breaking Head Stability Mould for 6' (152,4 mm) Marshall Samples |

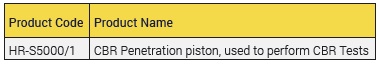

Repuestos y Consumibles

| Código | Descripción |

|---|---|

| B2-01-03-0051-13 | CBR Penetration piston, used to perform CBR Tests |

Especificaciones Técnicas

| 0.625 | 1.25 | 1.875 | 2.5 | 3.125 | 3.75 | 4.375 | 5 | 7.5 | 10 | CBR Ratio% | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||

| Sample 1 | Stress | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Load | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Sample 2 | Stress | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Load | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Sample 3 | Stress | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Load | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

Especificaciones Técnicas

| ASTM D1883 |

EN 13286-47 |

BS 1377 |

|---|---|---|

| Piston Diameter | 50 | mm |

| Penetration Rate | 1.27 | mm/min |

| Zero Suppresion | 0 | kN |

Especificaciones Técnicas

| Marshall Stability and Flow of Asphalt Mixtures | ||||||

|---|---|---|---|---|---|---|

| Company | --- | |||||

| Project | --- | |||||

| Address | --- | |||||

| Bitumen Content | --- | |||||

| Material Description | --- | |||||

| Mold Size - Test Temperature | --- | |||||

| Test Date | --- | |||||

| Average Bulk Density | --- | |||||

| Sample | Thickness (mm) | Correction Factor | Maximum L. (kN) | Stability (kN) | Flow (mm) | Marshall Q. (kN/mm) |

| Sample 1 | --- | --- | --- | --- | --- | --- |

| Sample 2 | --- | --- | --- | --- | --- | --- |

| Sample 3 | --- | --- | --- | --- | --- | --- |

| Sample 4 | --- | --- | --- | --- | --- | --- |

| Average | --- | --- | --- | --- | --- | --- |

| Tested By | Approved By | |||||

Especificaciones Técnicas

| 4"(in.)- 101.6 mm | 6"(in.)- 152.4 mm |

|---|---|

| ASTM D6927 | EN 12697-34 |

| • Standart | ○ Alternatif Metod |

| Penetration Rate 1.27 mm/min | --- |

Especificaciones Técnicas

| Diameter | 50 | mm |

| Initial Length (LO) | 100 | mm |

| Initial Area (A0) | 1963.495 | mm2 |

| Weight | 520 | g |

| Heig.-Diam. Ratio | 2 | |

| Density | 2.65 | g/cm3 |

| Test Speed | 1 | mm/min |

| Axial Strain Rate | 1 | %/min |

Especificaciones Técnicas

| Código | B2-01-03-0051-02 | B2-01-03-0051-04 |

|---|---|---|

| Product Name | CBR & Marshall & Unaxial Testing Machine | |

| Test Speed | 0,001 - 51 mm/min | |

| Capacity (kN) | 50 | 100 |

| Dimensions (cm) | 47x70x110 | 52X72X110 |

| Weight (kg) | 100 | 110 |

| Power Supply | 220 V, 50-60 Hz, 1 ph | |

Especificaciones Técnicas

| Código | Descripción |

|---|---|

| B2-01-03-0051-05 | Breaking Head Stability Mould for 4' (101,6 mm) Marshall Samples |

| B2-01-03-0051-06 | Breaking Head Stability Mould for 6' (152,4 mm) Marshall Samples |

Repuestos y Consumibles

| Código | Descripción |

|---|---|

| B2-01-03-0051-01 | CBR & Marshall & Uniaxial Frame, 50 kN |

| B2-01-03-0051-03 | CBR & Marshall & Uniaxial Frame, 100 kN |

| B2-01-03-0051-09 | Load Cell, 50 kN capacity |

| B2-01-03-0051-10 | Load Cell, 100 kN capacity |

| B2-01-03-0051-11 | Displacement Sensor, 25 x 0,01 mm |

| B2-01-03-0051-08 | H-Touch Pro Max CBR & Marshall & Uniaxial Control Unit |

| B2-01-03-0051-07 | H-GUI CBR & Marshall & Uniaxial Software |

Repuestos y Consumibles

| Código | Descripción |

|---|---|

| B2-01-03-0051-12 | Compression Platens with ball seating assembly |

Repuestos y Consumibles

| Código | Descripción |

|---|---|

| B2-01-03-0051-13 | CBR Penetration piston, used to perform CBR Tests |